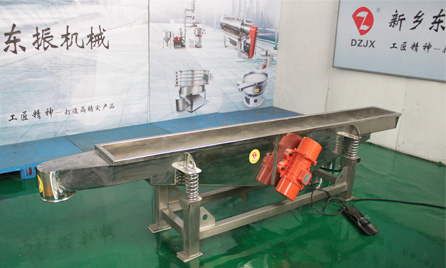

Xinxiang Dongzhen Machinery Co., Ltd was founded in 1986, located at No.6, Dongzhen Road, Xinxiang High-tech Industrial Development District.Here is a place with outstanding people, rich resources, superior geographical location, well-developed transportation and communication, and unique humanistic and natural advantages.

At the same time, our company always adheres to the development strategy of “people-oriented, honest management, scientific and standardized”, always adheres to the business philosophy of “taking science and technology as the guide, providing customers with high-end products and high-quality services as its own responsibility”, and always insisting on “paying attention to corporate reputation and bravely innovating technology , do a good job attentively” the company purpose, always adhere to the “diligence,rigorous, pragmatic, innovative” work style, dedicated to the development, production and application of advanced products.

Xinxiang Dongzhen Machinery Co., Ltd was founded in 1986, located at No.6, Dongzhen Road,Xinxiang High-tech Industrial Development Zone.Here is a place with outstanding people, rich resources, superior geographical location, well-developed transportation and communication, and unique humanistic and natural advantages.

At the same time, our company always adheres to the development strategy of “people-oriented,honest management, scientific and standardized”, always adheres to the business philosophy of “taking science and technology as the guide, providing customers with high-end products and high-quality services as its own responsibility”, and always insisting on “paying attention to corporate reputation and bravely innovating technology , do a good job attentively” the company

purpose, always adhere to the “diligence, rigorous, pragmatic, innovative” work style, dedicated to the development, production and application of advanced products.

Xinxiang Dongzhen Machinery R&D department clings to “promoting scientific and technological innovation to lead industrial transformation” as its core theme. Our high-end research and development team includes more than 20 personnel and they are well placed to develop and introduce up-to-date technology, ideas, and expertise to further enhance the ability to fulfill the ever-increasing demand and requirements, absorb the outstanding cutting-edge scientific and technological achievements to push technology development upwards and maintain itself in a leading position.

Xinxiang Dongzhen Machinery establishes a long-term profound cooperation with Engineering Machinery Research Institute, Screening and Conveying Research Institute, Mining Machinery Research Institute etc. What’s more, Xinxiang Dongzhen Machinery also builds a sound cooperation relationship with famous colleges and universities including Xinxiang University, Henan Institute of Science and Technology, Zhengzhou University of Light Industry, Henan Institute of Technology, Nanjing Institute of Technology etc., we fully play the advantages of engineering design and scientific research ability, turn advanced scientific research achievements into into engineering products and apply to production practices, which shows great engineering transformation ability.

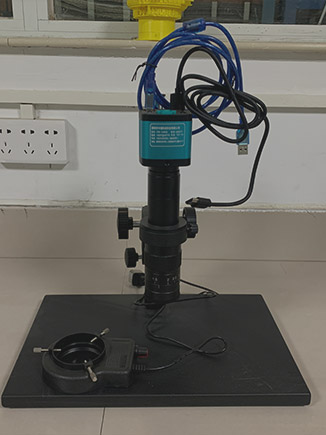

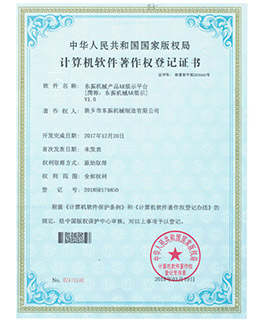

Through years’ development, Xinxiang Dongzhen Machinery has establish a three-dimensional co-design system,which utilizes the software of CAD, CAXA, PRO/E, SOLIDWORKS,UG, MSTERCAM as the core, through the collection of a variety of programs, complete functions, mechanical fine image can be drawn and presented to customers.

Meanwhile, Xinxiang Dongzhen Machinery pares no effort to carry out the advanced information construction so as to meet the cooperation needs of international projects, help enterprise to achieve sustainable development and improve market competitiveness. Till now, we have developed and introduced a number of mainstream software and up-to-date technology to enhance the design ability and management level in order to satisfy the ever-increasing demand and requirements of screening, conveying, mixing and pulverizing equipment all over the world.